Rapid Medical Mold Build for COVID-19 Response

Medical Filter Adapter

Overview

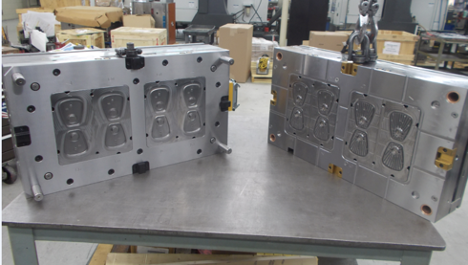

At the height of the COVID-19 pandemic, our customer was tasked with producing life-saving medical equipment at unprecedented speed. The project – initiated and backed by Vice President Mike Pence as part of the federal emergency response, required an extremely fast turnaround and absolute precision. Industrial Molds (Pyramid Molding Group) was selected to build a high-performance, eight-cavity hot runner mold for a critical medical filter adapter.

With more than 55 years of mold-building experience and a proven ability to deliver high-quality tools on accelerated timelines, our team committed to a six-week build – then beat it.

The Challenge

The medical filter adapter was essential to frontline COVID-19 treatments, and supply shortages meant that every day mattered. The customer needed:

- An eight-cavity hot runner mold capable of high-volume production

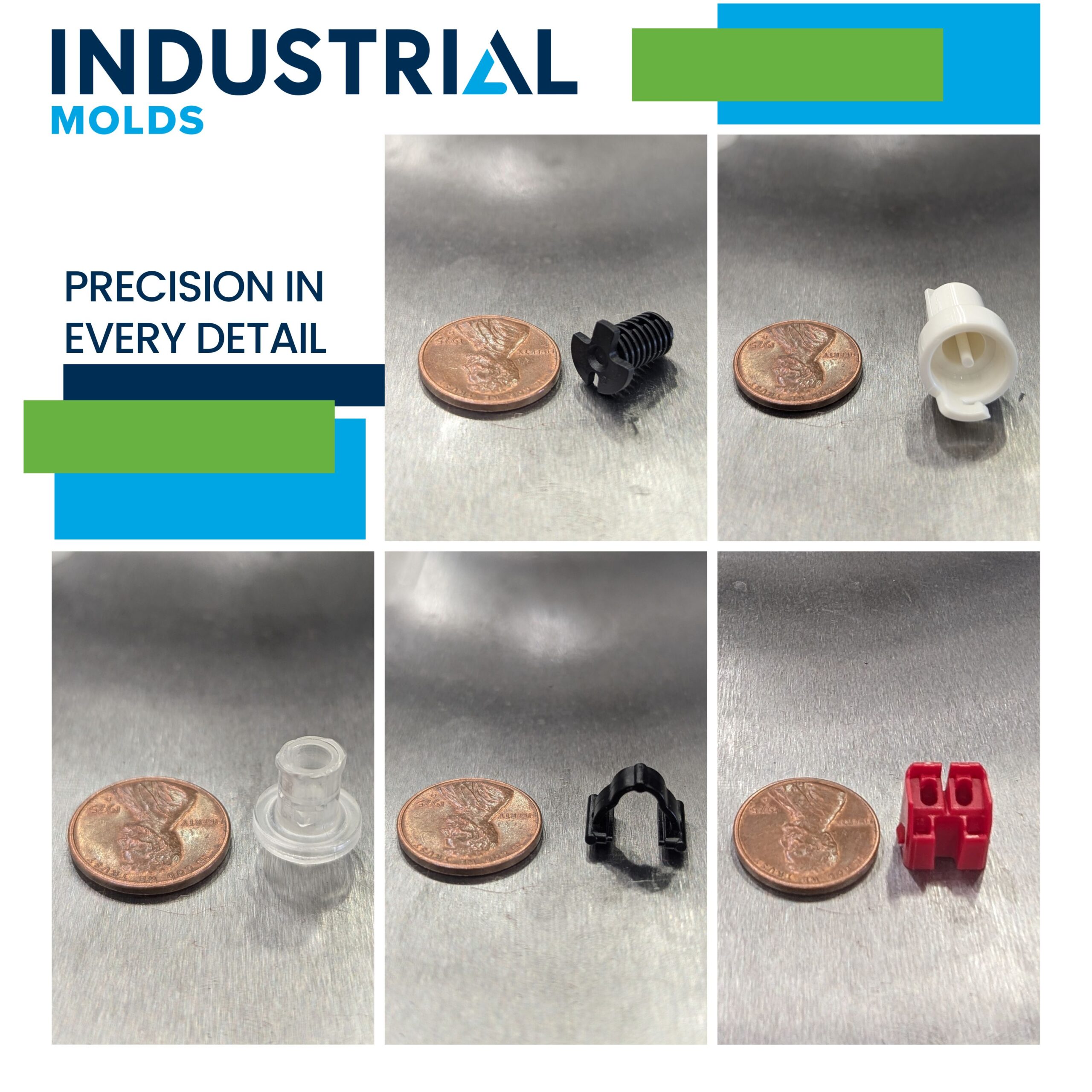

- Medical-grade precision with no room for error

- An accelerated 6-week timeline, far faster than industry norms

- Guaranteed first-shot success, with no time for iteration or grooming

This was a true emergency-response project requiring flawless execution, proactive communication, and a manufacturing partner capable of managing difficult turnaround demands.

The Execution

Already having a mold design intended to test for the flu, Industrial saved at least two weeks in Engineering. Our team mobilized immediately, activating multiple engineering and manufacturing disciplines within hours of project kickoff.

Day 2 – Preliminary Design & DFM

- Drafted the preliminary mold design

- Completed part modifications for Design for Manufacturing (DFM)

- Customer approval secured within 48 hours

Week 1 – Materials in Motion

- Finalized mold design concept

- Ordered all materials and components

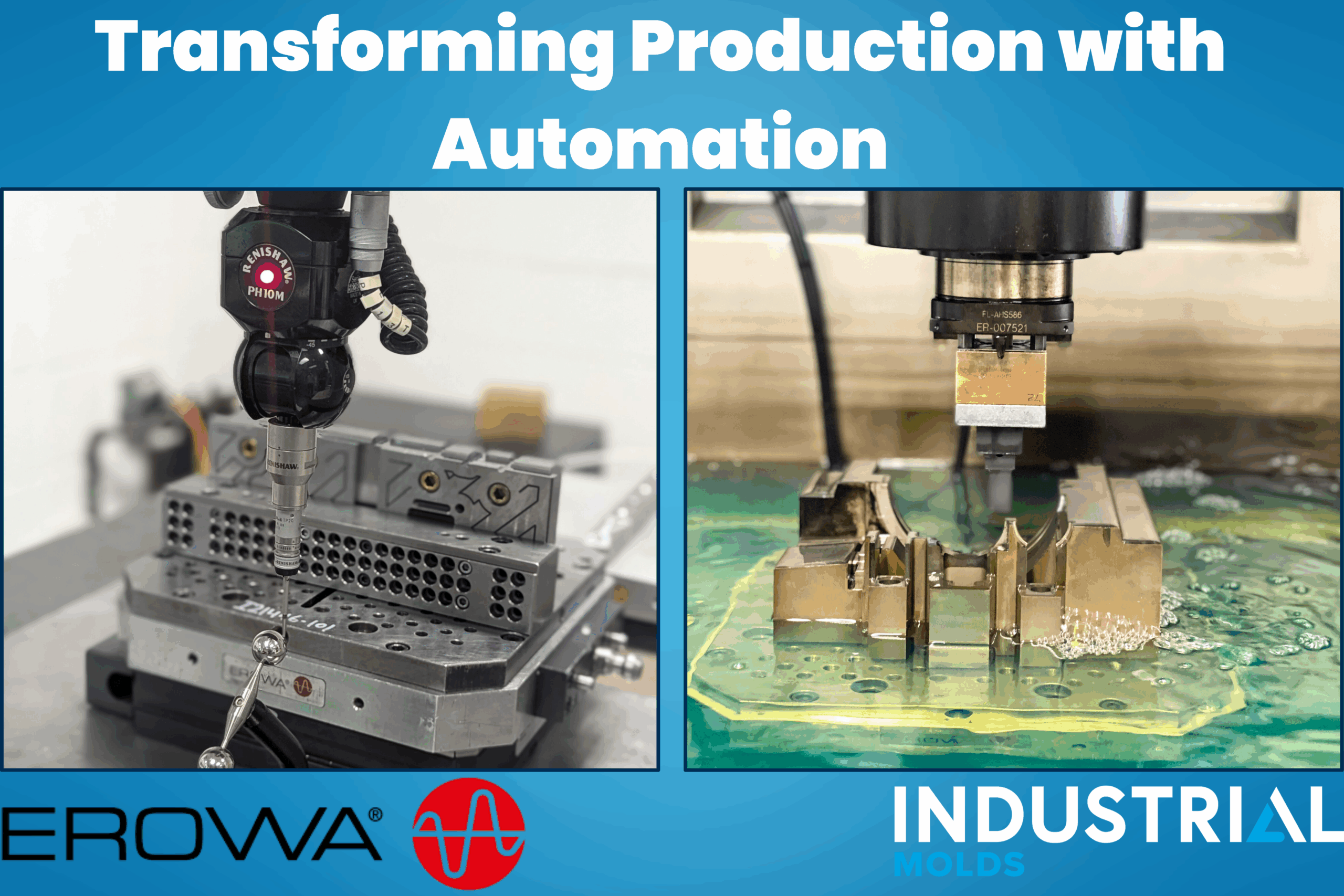

- Scheduled and sequenced the entire build in our ERP and Erowa-integrated workflows

Week 3 – Electrode Completion

- All electrodes were designed and built by the end of week three

- Simultaneous manufacturing across machining, EDM, polishing, benching, and assembly kept the project ahead of schedule

Week 5 & 6 – Tool Completion

- Mold was completed ahead of schedule and parts were approved off our CAD so the mold could go into production

- No dimensional grooming required – a rare accomplishment on a complex medical mold built this quickly

The Results

- Zero rework– tool approved immediately

- Production-ready

- Supported a nationally recognized, high-priority medical response initiative

This project reflects Industrial Molds ability to rise to national-level challenges with speed, accuracy, and fully integrated teamwork to deliver a medical grade mold.