Using the Power of Focus to Increase Throughput and Impact the Bottom Line

“We didn’t think it was possible, but we

had to – so we shifted our mindset

and changed the way we do things.” – Andy Peterson, Industrial Molds

AMBA Interview with Andy Peterson, Industrial Molds

Q: What led you to change how you manage throughput?

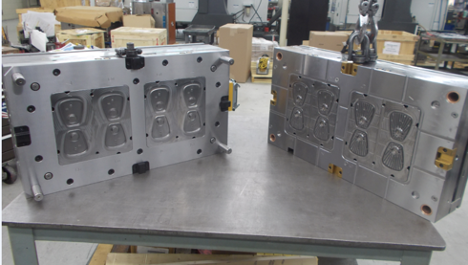

A: When our team was asked to make molds for COVID-19 testing kits during the pandemic, several of our other projects took a back seat – we had to get this done on time no matter what. This project was part of a case study that helped us realize what we were capable of when we’re focused on the task at hand. We learned that we could complete projects faster and more efficiently by working on fewer jobs at a time and giving them our undivided attention from start to finish.

Q: How is the new process communicated to your customers?

A: We tell our customers that we’ll hit the deadlines we’ve committed to but that their project may not start right away. We then explain our new operations process and how it has greatly improved our throughput and on-time deliveries – customers experience these improvements first-hand after just a few projects, so it’s an easy buy-in for them.

Q: What steps did you take to improve turnaround times and in what areas?

A: Working on fewer projects at a time has made it easier to spot areas for improvement. We started by identifying simple bottlenecks within each department and resolving them as quickly as possible. We found that fixing something small within one part of the process would sometimes eliminate bigger, more expensive issues in another. For example, rather than purchasing a fancy 5-axis machine we thought we needed, we resolved a bottleneck in the prep department by adding much less expensive equipment that eliminated the need for a 5-axis machine. We now meet every month to identify operational bottlenecks to ensure we continue to improve efficiencies facility-wide. Additionally, we’ve shifted our focus from the profitability of each job to each month, which means that we are taking on more short-term jobs than we have in the past. If a short-term project comes up, we schedule it right away – everything we’re going to do, almost down to the hour – allowing us to complete it quickly and efficiently.

Q: How have the new processes affected your workforce? What benefits / ROI have you realized thus far?

A: In the past, if we had eight weeks to work on something we would work on it for all eight weeks while working on several other long-term projects at the same time. There is now less work to manage all at once, allowing our team to be laser focused – we know everything there is to know about a couple of projects. With less stopping, restarting, queuing, etc., the new process has reduced stress for everyone in our shop. Instead of facing a daunting mountain of work and trying to remember the details for everything, we’re keyed into two or three projects – we get them done and out the door, then we move on to the next. Since making these operational changes, our workforce is more productive and our turnaround times have improved, which has led to an increase in sales of about 20 percent on an annual basis.