Case Study: How Industrial Molds Transformed Production with EROWA Automation

Introduction

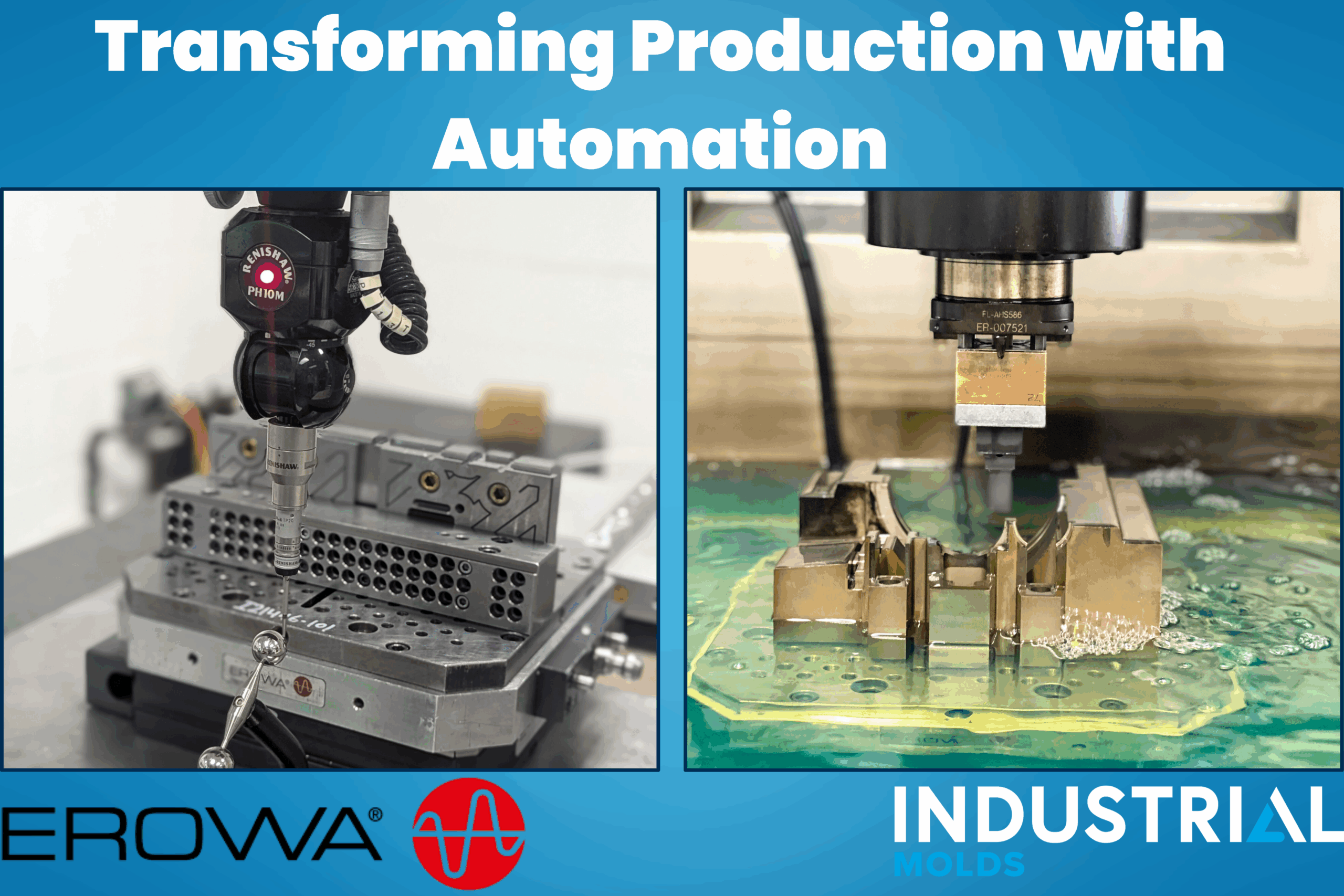

Industrial Molds has been building precision tooling, domestically, for over five decades, but, in 2005, the company recognized that staying competitive in high-mix, low-volume manufacturing required a new approach. Partnering with EROWA, Industrial Molds became an early adopter of automation technologies, integrating a complete Flexible Manufacturing Concept (FMC) – tooling, presetting, robots, and software into their operations. Today, their shop floor stands as a benchmark for what automation in mold making can achieve.

The Challenge: Staying Ahead in a High-Mix, Low-Volume Environment

Mold making is inherently custom work. Each block of steel requires unique programs, unique set-ups, and a commitment to precision measured in microns. Traditionally, this made automation difficult.

By 2005, Industrial Molds faced a bottleneck in graphite cutting. Operators were running at maximum capacity, yet downtime between setups left machines sitting idle too often. The company needed to improve throughput without sacrificing precision.

The Solution: Stepwise Integration of EROWA Technology

Industrial Molds began its automation journey with EROWA pallets in a single graphite cutting cell. “In using the pallet system, we quickly realized the benefits of automation,” shared Kris Grey, Industrial’s Production Manager. The results were immediate: reduced errors, faster throughput, and improved consistency.

Zero-point tooling played a key role in this efficiency. Because the steel is positioned identically every time it’s loaded onto any machine, and the pallet’s built-in skew allows the machine to automatically find the center point, setups are faster and more precise -eliminating manual alignment and reducing mistakes. Mistakes that previously occurred were no longer possible.

From there, Industrial Molds expanded into their Wire EDM department, then milling, and most significantly, into Quality via their CMM machines. This evolution led to a full-shop integration with EROWA’s Job Management System (JMS 4.0 MoldLine) software. Dan Pilolla, President of EROWA, stated, “Industrial Molds was an early adopter and embraces all four FMC segments: Tooling, Presetting, Robots, and Software. With EROWA’s powerful JMS software, all operators work off the same platform, tying production together from start to finish.”

FMC segments:

- Tooling – standardized pallets and holders reduce errors and setup time.

- Presetting – offline preparation ensures machines are cutting, not waiting.

- Robots – cells now run lights-out, maximizing spindle utilization.

- Software (JMS) – scheduling and data management orchestrate the entire shop floor from one platform.

The Results: Efficiency, Accuracy, and Workforce Agility

The impact of automation at Industrial Molds has been measurable and profound. As Kris Grey explains, “Before automation, we had a team of 6 operators in our Wire EDM Department to run 11 EDM Machines. With EROWA, Industrial outputs more production with only 2 Wire EDM machines and only 1 operator.” In addition, the training time for a new hire is condensed. Kris explains, “Before EROWA, 7 years of experience was required to work in our EDM Department, now we can get a newer operator up and running in about two weeks.”

Dan Pilolla adds, “With today’s labor market, companies need to be as efficient as possible, which means maximizing machine up-time, including lights-out manufacturing.”

Key Takeaway: Growth by Solving Bottlenecks While Maintaining Quality

At its core, Industrial Molds’ automation journey has been about eliminating bottlenecks without compromising quality. EROWA Technology has enabled Industrial Molds to grow by solving production challenges while maintaining the highest levels of precision.

This balance – efficiency with accuracy- is what differentiates Industrial Molds in the market and ensures long-term competitiveness.

The Partnership: Why Industrial Molds Stands Out

“Industrial’s early adoption of our JMS system made them a cutting-edge mold maker in the U.S. market, with software capable of managing an entire shop floor,” shared Brendan Perry, Sales Manager with EROWA.

Industrial Molds is among the rare shops to embrace all four FMC segments. “While many shops use EROWA products, not all embrace all four FMC pillars,” stated Dan Pilolla. Evenmore unique is their use of JMS in a high-mix, low-volume environment. As Brendan Perry noted, “Many shops – especially job shops – still today do not understand that automation is not exclusively for the realm of production manufacturing. Perry went on to emphasize how Industrials adoption of all four pillars was so unique; “Where most assume automation isn’t possible, Industrial Molds demonstrated that even with unique, day-to-day work, automation can be fully leveraged.”

Looking Ahead: Automation as a Competitive Imperative

For Industrial Molds, automation isn’t just about machines – it’s about competitiveness in a tight labor market. “Having high-end mold makers like Industrial Molds as a benchmark reinforces EROWA’s principles to improve efficiency and throughput without any sacrifice in quality,” reinforces EROWA’s President and COO.

Bob Davila, Marketing Manager reiterated, “Industrial Molds visionary and forward-thinking ability has propelled them to the forefront of American manufacturing.”

Conclusion

Industrial Molds’ journey with EROWA demonstrates what’s possible when a mold maker not only invests in automation but embraces it across the entire value chain. Their early adoption, methodical integration, and commitment to continuous improvement have made them a pioneer in the industry.

Contact Information:

Industrial Molds, a Division of Pyramid Molding Group

Becca Peterson

Director of Business & Community Development

EROWA

Davila Bob

Marketing Manager