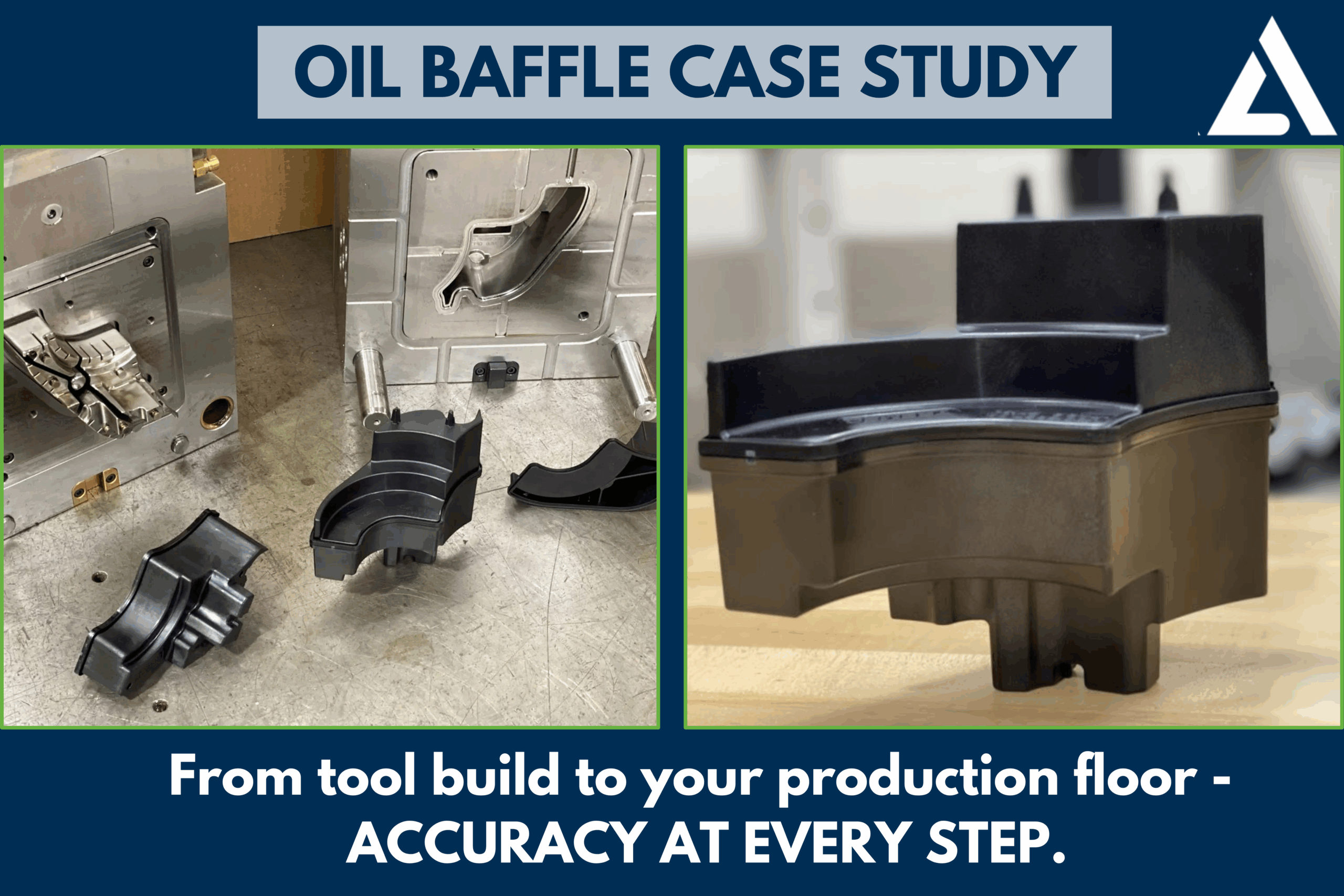

The Oil Baffle Story

A leading manufacturer of torque transfer solutions came to Industrial Molds with a unique oil baffle challenge for a next generation vehicle. The issue wasn’t molding, but design: the part had to weigh exactly 221 grams to keep the new transmission balanced.

The Problem:

- OEM transmission part too heavy

- Target: 221g vs. initial 980g

- Needed 77% reduction

- Tight tool build timeline

The Design Challenge

Our engineering team worked on a concept to core out the part, which left us with two halves of the oil baffle. The next step was finding a way to join them. Plastic welding quickly emerged as the best option, and given our long history of success with Dukane, a global leader in plastic welding solutions, they were selected to partner on this need. Together, we developed a new design where both halves would be joined using vibration welding – a proven technique in automotive and medical applications.

The Solution

The final design was a shell structure, vibration-welded along a seam that provided just enough surface area for the weld. Space limitations inside the transmission restricted the seam to only 30% of the size typically recommended, which made precision even more critical. The most unique feature of this design was a flash trap engineered into the seam to capture all debris created during welding. Without it, stray material in the oil-filled transmission could cause part failure. Additional design elements, such as strategic ribs, were also incorporated to provide stability and prevent sinks.

The Test

After extensive technical discussions, our teams agreed the design was ready for production. The challenge then shifted to timing: the customer required the tool in just 14 weeks, while the typical lead time for a complex tool and welding equipment is 18–20 weeks.

By expediting the build and leveraging our state-of-the-art tooling equipment, we delivered T0 samples by week 12 and ahead of schedule. The parts were rigorously leak-tested and certified to withstand pressures up to 20 PSI and temperatures ranging from -20°C to 140°C, ensuring performance and reliability in the field.